Manufacturer for Ppr Y-Tee Pipe Fitting Mould - CPVC Tee Pipe Fitting Mould – Longxin

Manufacturer for Ppr Y-Tee Pipe Fitting Mould - CPVC Tee Pipe Fitting Mould – Longxin Detail:

Introduce

Customers who consult CPVC Tee Pipe Fitting Mould, please provide the following detailed requirements:

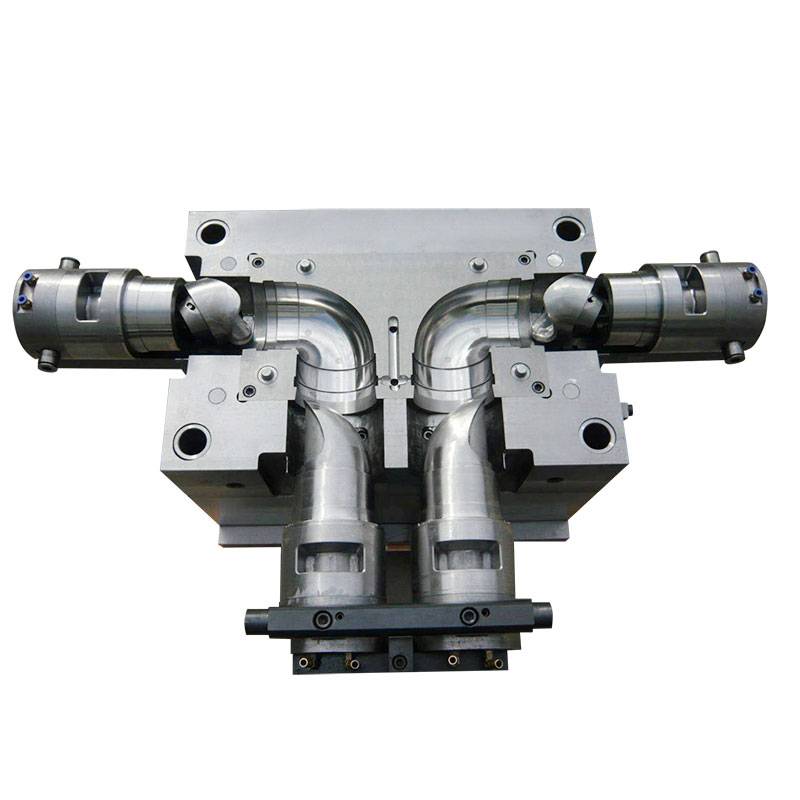

1. CPVC Tee Pipe Fitting Mould product picture and size, or (3D drawing)

2. How many cavities for different parts

3. The unit price needs to know the weight and raw materials

FAQ:

Finally, a pair of pipe fitting molds have been made. Next, we have to test the effectiveness of the mold, that is, mold trial. Then put it into production, and how to maintain the mold during production, so that the mold can be in a better working condition and let us reap the greatest benefits?

Below we will introduce the things that we should pay attention to when trying out our pipe fitting molds for this CPVC Tee Pipe Fitting Mould:

1. Whether the mold opening and closing is smooth, and whether the ejection is smooth.

2. Pay attention to the position of the mold gate and the way of glue feeding, the size of the gate and the size of the cavity, and select the appropriate pressure, speed, and material volume for injection molding.

3. After the mold heats up, carefully check whether all the matching parts of the mold are too hard, and then confirm the bonding line and exhaust. After the product is full, ask the quality personnel to confirm the size and appearance.

4. During the mold production process, check the mold settings and safety devices to let the operating staff understand the possible problems in the process. After the production is completed, the lower mold or standby needs to take necessary measures for the machine and mold.

5.When the mold is not in production, the pipe fitting mold should be maintained. First check the mold and determine the maintenance method. If you need to disassemble the parts, first check whether there is a clear mark. After the maintenance of the parts is completed, the assembly should be matched and seated. After the assembly is completed, first confirm the sequence of the mold. Pay attention to the careful inspection and confirmation of the first piece after each maintenance, and the production can be continued after the quality personnel confirm OK.

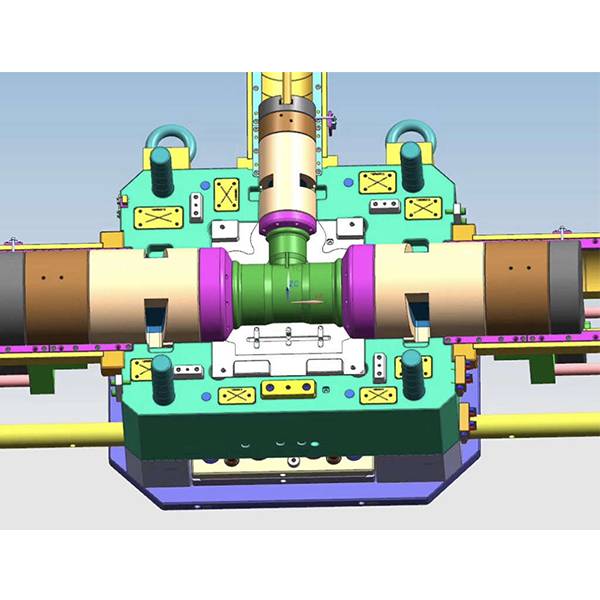

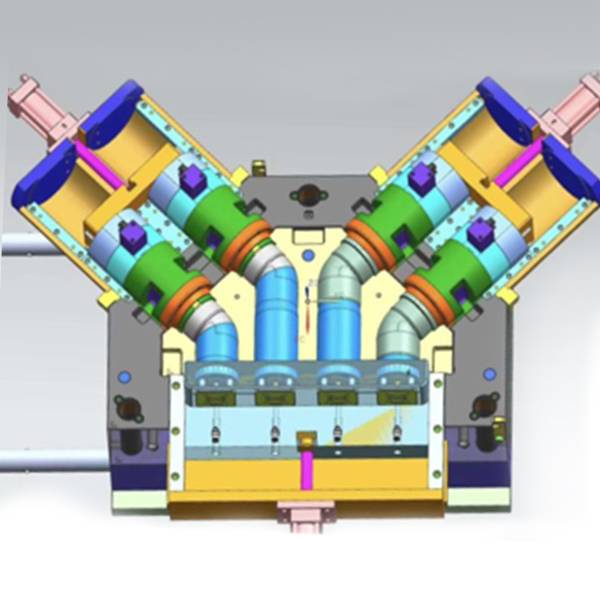

Product detail pictures:

Related Product Guide:

We regularly perform our spirit of ''Innovation bringing progress, Highly-quality making certain subsistence, Administration marketing benefit, Credit score attracting customers for Manufacturer for Ppr Y-Tee Pipe Fitting Mould - CPVC Tee Pipe Fitting Mould – Longxin , The product will supply to all over the world, such as: UK, Karachi, London, Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant experienced knowledge, to develop advanced production equipment and production process , to create the first-call quality goods, reasonable price , high quality of service , quick delivery , to present you create new value .

The goods are very perfect and the company sales manager is warmful, we will come to this company to purchase next time.