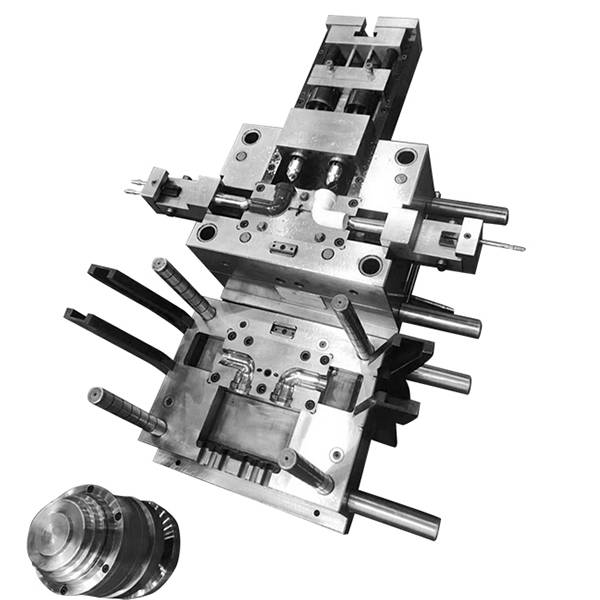

CPVC Elbow Pipe Fitting Mould

Introduce

The product introduction of our CPVC elbow mold is as follows :

[Mold material] 45# quenched and tempered, 60# quenched and tempered, P20, P20H, 718, 718H, 2738, 7138, NAK80, S136, SKD61, etc. according to customer needs.

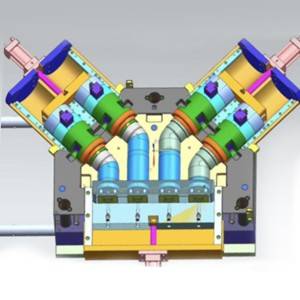

[Mold design software] Moldflow, UG, PROE, AUTOCAD, Cimatron E, etc.

[Mold cooling system] Optimized design of circulating water to improve production efficiency and reduce your costs.

[Mold mid-term treatment] quenching and tempering to improve hardness.

[Mold post-treatment] (The nitriding treatment temperature is low, the deformation is small, and no quenching is required, it has high surface hardness (greater than HV8500) and wear resistance.

Details

[Mold life] Normal use is not less than 500,000 times.

[Transportation method] Before the mold is shipped, the clamping piece must be installed, wrapped with stretch film, and then packed in a wooden box. The packaging is sturdy and rust-proof, avoiding damage to the mold during transportation, and finally logistics transportation to the customer

[Place of Origin] Huangyan, Taizhou, Zhejiang.

FAQ:

1. Pipe fitting mould What should I do if the ejector pin is bent or broken during normal production?

Now we are targeting this CPVC elbow pipe fitting mold

Make a detailed introduction:

The self-made ejector rods are of better quality, but the processing cost is relatively high. Nowadays, the mold structure generally uses standard parts, and the quality is at the conventional level. If the gap between the ejector pin and the guide hole is too large, material leakage will occur; but if the gap is too small, the mold temperature will increase during injection molding, which will cause the ejector pin to expand and become stuck, sometimes even after the ejector pin is ejected for a certain distance It will not move and deform, resulting in the next mold closing, the higher ejector rod cannot be reset and directly hit the cavity.

If CPVC Elbow Pipe Fitting Mould is generated normally

When this problem occurs, the ejector pin should be re-ground. The mold structure retains a 10-15 mm mating section at the front end of the ejector pin, and the middle part is ground 0.2 mm smaller. After all ejector rods are assembled, their fit clearance must be strictly checked, generally within 0.05-0.08 mm, to ensure that the entire ejector mechanism can advance and retreat freely.

2. What should I do if CPVC Elbow Pipe Fitting Mould has poor cooling or water leakage during the production process?

The cooling effect of CPVC Elbow Pipe Fitting Mould directly affects the product quality and production efficiency. Such as poor cooling, large shrinkage of the product, or uneven shrinkage, resulting in warping deformation and other defects; on the other hand, the Fitting Mould is overheated in whole or part, so that the mold cannot be formed normally and production is stopped. In severe cases, the movable parts such as ejector rods may be thermally expanded. Dead and damaged.

The design and processing of the cooling system depends on the shape of the product. Don't omit this system because of the complicated structure of the pipe fitting mold or the difficulty in processing, especially for large and medium-sized molds. The cooling problem must be fully considered.

The Exhibition